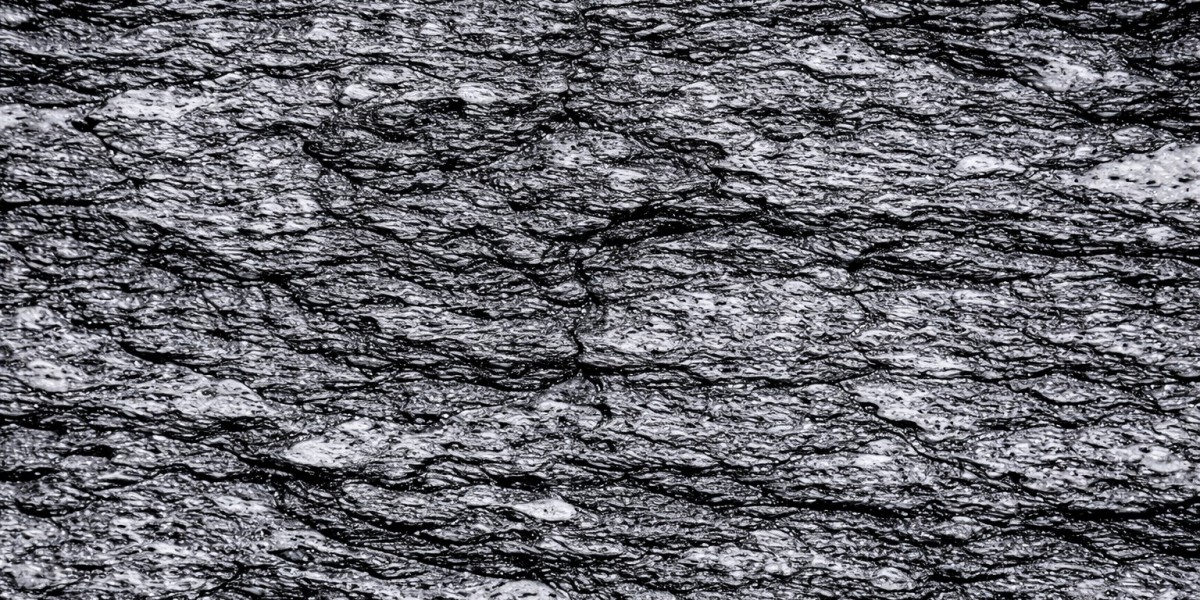

Graphite is a naturally occurring form of carbon, widely valued for its unique combination of physical and chemical properties. One of the most important characteristics of graphite is its density, which directly affects its applications in batteries, lubricants, electrodes, and refractory materials. Graphite density is a key parameter for engineers, chemists, and manufacturers seeking to optimize material performance.

Understanding Graphite Density

Graphite density refers to the mass of graphite per unit volume, usually expressed in grams per cubic centimeter (g/cm³). It varies depending on the type and quality of graphite. Natural graphite typically has a density ranging from 2.09 to 2.23 g/cm³, while synthetic graphite can have higher densities due to controlled manufacturing processes. Density influences mechanical strength, electrical conductivity, and thermal properties.

Factors Influencing Graphite Density

Porosity: More porous graphite has lower density because of the trapped air pockets.

Purity: Impurities such as ash or non-carbon elements can increase or decrease density.

Manufacturing Method: Synthetic graphite is often denser due to high-temperature processing and compression.

Crystal Structure: The alignment and stacking of graphite layers (graphene sheets) affect how compact the material is, thus influencing density.

Applications Based on Graphite Density

1. Battery Electrodes:

High-density graphite is widely used in lithium-ion and other battery electrodes because it offers excellent conductivity and mechanical stability.

2. Lubricants:

Low-density, porous graphite is ideal for dry lubrication, reducing friction and wear in mechanical systems.

3. Refractory Materials:

Dense graphite is resistant to high temperatures, making it suitable for furnace linings, crucibles, molds, and high-temperature industrial processes.

4. Industrial Components:

Graphite density determines the suitability of materials for precision parts such as gaskets, seals, and brushes. Engineers select graphite density to ensure components withstand mechanical stress and thermal variations.

Methods to Measure Graphite Density

Archimedes’ Principle: Measures the volume displaced by a graphite sample in liquid to calculate density.

Helium Pycnometry: Determines the true density by gas displacement, removing the effect of porosity.

X-ray Crystallography: Analyzes lattice structure to estimate theoretical density.

Importance of Graphite Density

Graphite density is crucial in determining the material’s thermal conductivity, electrical performance, and mechanical strength. Proper selection of graphite density ensures reliability in applications ranging from batteries and electronics to aerospace and metallurgy. It also helps optimize production processes and improve material efficiency.

Conclusion

Graphite density is a vital property that impacts its industrial, scientific, and technological applications. Understanding how density varies, how it is measured, and its effects on material performance allows manufacturers and researchers to select the right graphite for specific uses. From high-density synthetic graphite in battery electrodes to low-density graphite in lubricants, proper knowledge ensures safety, efficiency, and long-term performance.