Why Epoxy Matters in Modern Industry

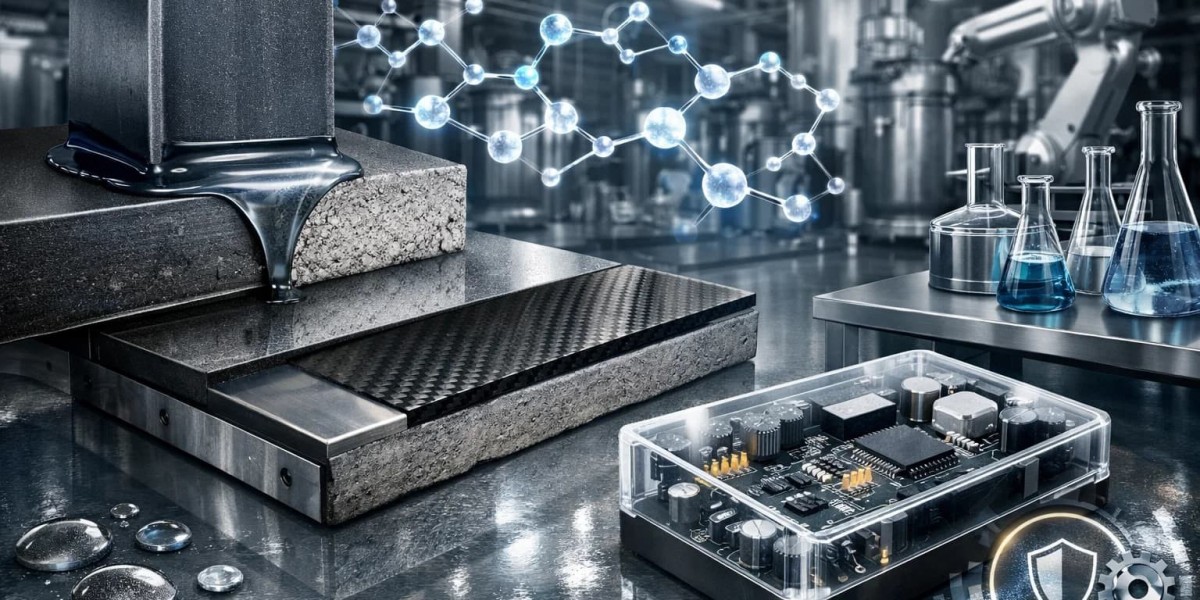

In today’s rapidly evolving industrial landscape, materials that offer superior performance, reliability, and adaptability are more critical than ever. Epoxy is one such material, renowned for its exceptional strength, chemical resistance, and versatility. Its ability to adhere to a variety of surfaces, including concrete, metal, and wood, makes it an indispensable choice across multiple sectors, from manufacturing and construction to research and technology.

The demand for epoxy-based solutions has grown steadily due to their ability to combine mechanical strength with long-term durability. Epoxy flooring, epoxy adhesive systems, and other specialized formulations deliver practical solutions for environments that face high traffic, chemical exposure, or mechanical stress. Beyond performance, epoxy materials offer unique benefits such as seamless surfaces, minimal maintenance, and adaptability to specific operational requirements.

This article explores the science behind epoxy, highlighting its core properties, industrial applications, and why it continues to be a preferred material for modern infrastructure. By understanding how epoxy works, industries can harness its full potential for sustainable, high-performance outcomes.

What Is Epoxy? A Scientific Overview

Epoxy refers to a class of thermosetting polymers formed by the chemical reaction between epoxy resins and hardeners. When these components combine, they undergo a process called cross-linking, forming a rigid, three-dimensional network. This reaction is irreversible, resulting in a material that is exceptionally strong, chemically resistant, and dimensionally stable.

At the molecular level, the resin contains epoxide groups, which react with amines, anhydrides, or other curing agents to form covalent bonds. This structure gives epoxy its hallmark properties, including high tensile strength, resistance to shrinkage, and excellent adhesion. Unlike conventional materials, epoxy can be formulated to meet precise industrial specifications, allowing manufacturers to tailor products for specific applications.

The importance of formulation control cannot be overstated. The choice of resin, hardener, additives, and curing conditions determines the performance characteristics of the final product. This level of precision is why epoxy flooring, adhesives, and coatings outperform traditional materials in demanding environments.

By understanding the chemistry behind epoxy, industries can leverage its unique attributes to achieve reliable, long-lasting, and versatile solutions. Its ability to bond, protect, and enhance surfaces underpins its widespread adoption across sectors.

The Core Strength of Epoxy Materials

Epoxy materials are celebrated for their mechanical strength and adhesion capabilities. Their molecular structure allows them to bear substantial loads without deforming, making them ideal for industrial and commercial applications. Epoxy adhesive systems, in particular, create a durable bond between diverse surfaces, including concrete, metals, plastics, and wood. This bonding strength surpasses that of many mechanical fasteners, reducing the need for nails, screws, or welding in certain applications.

In addition to adhesion, epoxy materials resist cracking, shrinkage, and deformation under stress. This stability ensures that structures retain their integrity over time, even under heavy loads or fluctuating environmental conditions. Industrial applications, such as machinery components, flooring, and protective coatings, benefit from this resilience.

Long-term structural stability is another key advantage. Properly formulated epoxy can maintain its properties for decades, offering a reliable solution for critical projects. From reinforcing concrete surfaces to providing high-performance coatings for industrial equipment, epoxy’s strength ensures operational efficiency and safety.

By integrating epoxy materials, industries gain a robust, versatile solution capable of withstanding mechanical, chemical, and environmental challenges, enhancing the reliability of their infrastructure.

Durability That Withstands Extreme Conditions

Epoxy is renowned for its ability to endure harsh conditions that would quickly degrade conventional materials. It exhibits exceptional resistance to chemicals, moisture, heat, and abrasion, making it suitable for high-traffic and industrial environments. From chemical plants to commercial kitchens, epoxy flooring and coatings protect surfaces while maintaining their structural and aesthetic integrity.

Environmental exposure, such as ultraviolet light, humidity, or fluctuating temperatures, has minimal impact on properly formulated epoxy. This durability reduces maintenance requirements and ensures longevity, offering significant cost savings over time. Surfaces coated with epoxy remain resistant to stains, wear, and erosion, which is essential for facilities requiring strict hygiene or operational efficiency.

In addition to physical and chemical resistance, epoxy can withstand repeated mechanical impact and vibration. Its ability to distribute stress evenly prevents cracks and deformation, ensuring that floors, adhesives, and potting materials remain intact even under heavy-duty use.

Industries increasingly recognize that investing in epoxy solutions enhances safety, reduces repair costs, and extends the life of critical infrastructure. Durability, coupled with minimal maintenance, positions epoxy as an indispensable material for long-term performance in extreme operating conditions.

Epoxy Flooring: Engineering Strength Beneath Your Feet

Epoxy flooring is a high-performance solution designed to meet the demands of modern industrial, commercial, and residential environments. Unlike conventional flooring materials, epoxy creates a seamless, non-porous surface that combines durability, chemical resistance, and aesthetic appeal. This makes it ideal for warehouses, factories, hospitals, and even residential spaces where hygiene and safety are priorities.

One of the most significant advantages of epoxy flooring is its mechanical strength. The cross-linked molecular structure allows the floor to resist heavy loads, impacts, and abrasion. This makes it particularly suitable for high-traffic areas where traditional flooring would wear quickly. Additionally, epoxy flooring provides slip resistance, enhancing workplace safety and reducing the risk of accidents.

Maintenance is another key benefit. Epoxy floors are easy to clean, resist staining, and do not require frequent repairs or replacements. The seamless nature of the surface also prevents water penetration, protecting the underlying substrate from damage.

Epoxy flooring’s adaptability allows it to be customized for specific operational needs. From industrial coating systems to decorative finishes, it delivers long-term performance and visual appeal. Its combination of strength, chemical resistance, and versatility ensures that epoxy flooring continues to be a preferred choice across diverse sectors.

Epoxy Adhesive Systems: Precision Bonding Across Industries

Epoxy adhesive systems provide unmatched bonding strength by forming durable chemical bonds at the molecular level. When applied, the resin and hardener penetrate surface microstructures, creating a cohesive and highly resilient joint. This precision bonding makes epoxy adhesives ideal for construction, manufacturing, and engineering applications.

Compared to mechanical fasteners, epoxy adhesives offer several advantages. They distribute stress more evenly, reduce the risk of structural failure, and maintain performance under vibration, thermal cycling, or chemical exposure. High shear strength and environmental resistance ensure reliability in demanding conditions, from assembling machinery to structural repairs.

The versatility of epoxy adhesives allows them to bond dissimilar materials, including metals, composites, concrete, and wood. This capability opens new possibilities for designers and engineers, reducing the need for complex mechanical solutions.

Industries increasingly rely on epoxy adhesive systems to ensure safety, durability, and long-term performance. Their ability to provide a strong, reliable bond under diverse conditions highlights why epoxy continues to outperform conventional bonding methods.

Epoxy Potting: Protecting Critical Components

Epoxy potting involves encapsulating electronic or mechanical components in a protective epoxy compound. This process provides electrical insulation, vibration resistance, and protection against moisture, chemicals, and physical damage. Epoxy potting ensures that sensitive components maintain performance even in challenging operating conditions.

Industries such as electronics, automotive, and industrial equipment rely on epoxy potting to enhance product longevity and reliability. The chemical and mechanical stability of epoxy prevents short circuits, corrosion, and structural fatigue, safeguarding both performance and safety.

In Pakistan, the demand for epoxy potting solutions has grown significantly, reflecting the expanding industrial supply chain. Manufacturers specializing in epoxy potting provide tailored solutions to meet specific requirements, from small-scale electronics to large industrial machinery.

By employing high-quality epoxy potting compounds, industries can reduce equipment failures, minimize maintenance, and improve overall operational efficiency, highlighting the essential role of epoxy in critical applications.

Tile Bonding Solutions and Construction Applications

Epoxy-based tile bonding materials have revolutionized modern construction. Unlike traditional cement-based adhesives, epoxy tile bonds offer superior water resistance, flexibility, and load tolerance. This ensures long-lasting installations in high-moisture or high-traffic areas.

Epoxy adhesives for tiles maintain structural integrity under temperature fluctuations and heavy mechanical stress. They are particularly useful for industrial flooring, commercial kitchens, bathrooms, and swimming pools where durability and water resistance are paramount.

The growing demand for professional tile bonding solutions in Pakistan highlights the need for reliable manufacturers that deliver consistent, high-performance products. Epoxy-based tile bonds reduce maintenance, prevent cracking, and enhance the aesthetic appeal of tiled surfaces.

Advanced Manufacturing and Quality Control in Epoxy Production

Precision in manufacturing is critical for delivering high-quality epoxy products. Advanced equipment and controlled production environments ensure that resins, hardeners, and additives are accurately measured, mixed, and cured.

Quality control protocols, including GLP and cGMP standards, ensure consistency, safety, and performance reliability. Rigorous testing of mechanical, chemical, and thermal properties guarantees that each batch meets industrial requirements.

By maintaining strict quality assurance, manufacturers can provide epoxy flooring, adhesives, potting compounds, and coatings that perform consistently across industries. Compliance with international benchmarks further underscores the reliability and safety of these products.

Sustainability and Environmentally Responsible Epoxy Solutions

Modern epoxy manufacturing increasingly prioritizes eco-friendly practices. Energy-efficient production processes, reduced emissions, and responsible waste management are essential components of sustainable epoxy solutions.

Long product life cycles contribute to environmental responsibility by minimizing the frequency of replacements and associated resource consumption. Formulations are evolving to balance performance with reduced environmental impact, reflecting a commitment to sustainable industrial development.

Industries adopting environmentally responsible epoxy solutions benefit from both performance and compliance with global sustainability standards. This alignment ensures that projects meet regulatory requirements while supporting a greener future.

Industries That Rely on Epoxy Technology

Epoxy materials have become essential across a wide range of industries:

Building and Construction: Enhancing structural strength, waterproofing, and corrosion resistance.

Pharmaceutical and Laboratory Environments: Providing chemical resistance, safety, and hygiene.

Process and Manufacturing Industries: Delivering reliable coatings and adhesives for machinery and infrastructure.

Agriculture and Storage Facilities: Offering durable, weather-resistant coatings for equipment and storage solutions.

Research, Education, Fibers, and Composite Materials: Supporting academic advancements and industrial material development.

The adaptability of epoxy allows each sector to address its unique challenges, whether it involves heavy mechanical loads, chemical exposure, or environmental stresses. Its consistent performance and reliability make epoxy a cornerstone material in industrial innovation.

The Future of Epoxy: Innovation and Global Expansion

Research and development continue to drive innovation in epoxy technology. New formulations, advanced additives, and tailored solutions are expanding its applications across industries worldwide.

International demand for high-performance, sustainable epoxy solutions is rising, prompting manufacturers to focus on precision, quality, and eco-friendly production. Customization enables industries to optimize performance for specific operational conditions, from industrial flooring to specialized adhesive systems.

As epoxy continues to evolve, it solidifies its role as a versatile, reliable, and sustainable material for modern infrastructure. Its combination of strength, durability, and adaptability ensures that it remains integral to industrial growth and global expansion.

Conclusion: Why Epoxy Continues to Shape Modern Infrastructure

Epoxy’s exceptional strength, durability, and versatility make it a vital material for industrial, commercial, and residential applications. From epoxy flooring to adhesive systems and potting compounds, its science-driven design ensures reliable performance under demanding conditions.

By selecting the right epoxy solution, industries can achieve long-term operational efficiency, cost savings, and enhanced safety. Epoxy’s resistance to chemicals, moisture, heat, and mechanical stress ensures longevity, reducing maintenance and replacement needs.

As the material continues to advance through research, innovation, and sustainable manufacturing practices, its relevance across industries only grows. Epoxy remains a future-ready solution, providing unmatched value, adaptability, and performance. Its role in shaping modern infrastructure highlights the importance of understanding and leveraging this high-performance material.